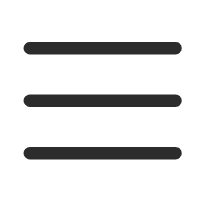

Material: SS201, SS304, SS316L, SS430

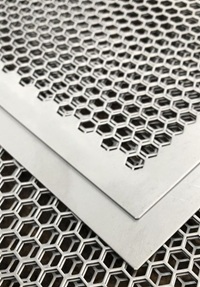

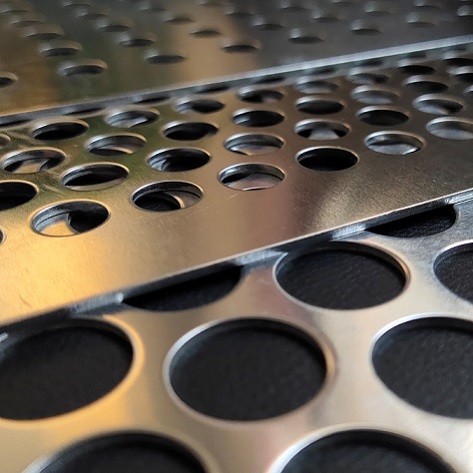

Type of Mesh: Perforated Mesh

Thickness: Ranging from 0.3mm to 10mm

Width: Within 1500MM / 4.92 feet / 59.05 inch

Length: Within 3000MM / 9.84 feet / 118.1 inch

GET A QUOTE

Stainless Steel Perforated Sheet – An Exceptional Combination of Raw Strength, Adaptability, and Aesthetics

Appropriate selection of modern materials in architecture and construction pays attention to functionality, modern design, and overall aesthetics. A modern metal that finds increased usage in modern architecture is stainless steel perforated sheets.

Stainless steel perforated sheet possesses marked strength and corrosion resistance, while also offering design flexibility that meets the needs of architects, engineers, and builders for elegance and functionality.

As one of the leaders in providing architectural and industrial solutions, Metart Building Tech is well known for offering high-quality stainless steel perforated sheets for different applications. With stainless steel perforated sheet selling under the Metart name, customers can rest assured that the products meet safety, durability, and modern aesthetic standards as they are produced by Metart, a factory known for its precision and care in crafting industrial products.

What is a Stainless Steel Perforated Sheet?

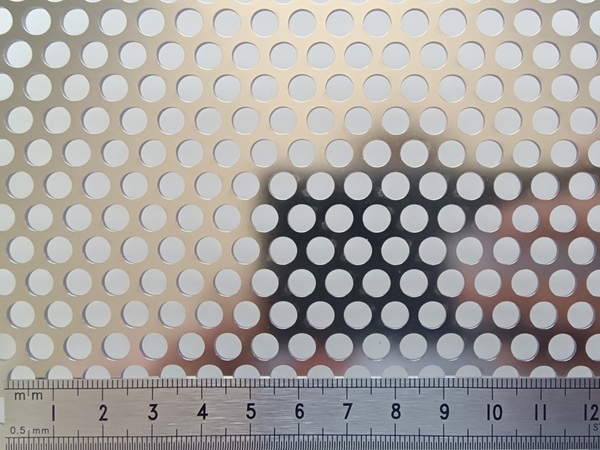

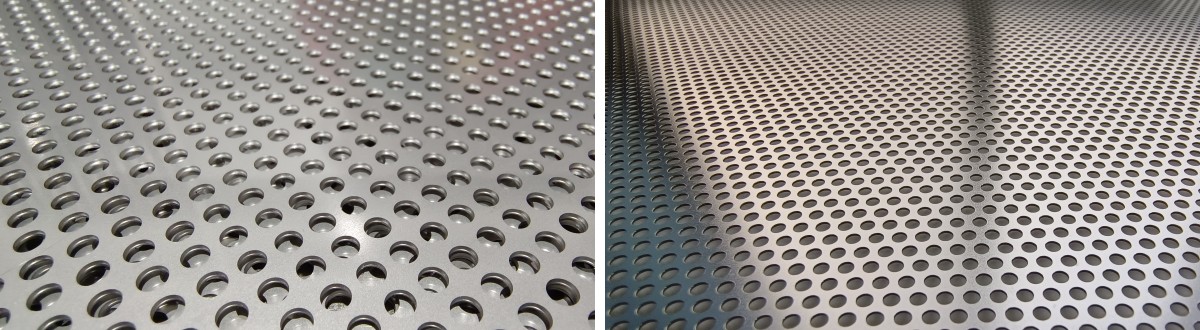

A stainless steel perforated sheet is a metal sheet that is punched using modern technology into different patterns as well as holes, slots, and decorative shapes. Apart from aesthetics, these stainless steel perforated sheets are widely used in ventilation, filtration, as well as sound and safety shields.

The sheets are often produced from high-grade stainless steel due to its resistance to rust, corrosion, and wear, even in some of the most challenging environments. Metart Building Tech concentrates on the manufacture of stainless steel perforated sheets, which have design versatility and a high strength-to-weight ratio.

Commonly Used Stainless Steel Materials

SS304 – The most widely used stainless steel grade, offering a cost-effective balance of strength and corrosion resistance for general applications.

SS316L – Commonly referred to as marine grade stainless steel, it provides significantly higher corrosion resistance than SS304, especially in chloride or saline environments.

SS201 – The most economical stainless steel option, suitable for applications where lower corrosion resistance is acceptable.

Other customized options – Available upon request, including duplex stainless steel such as UNS S31803 (2205) duplex perforated sheets and UNS S32750 (2507) super duplex perforated sheets, which deliver exceptional strength and superior corrosion resistance in highly demanding environments.

Regular Sheet Size for Perforated Stainless Steel

► 1000mm × 2000mm (3.28 ft × 6.56 ft / 39.37 in × 78.74 in)

► 1219.2mm × 2438.4mm (4 ft × 8 ft / 48 in × 96 in)

These two dimensions are the most commonly used sheet sizes in the perforated stainless steel industry in China.

They are widely available in the market, allowing us to source them quickly and begin punching jobs immediately after receiving customers' purchase orders.

If you require a different width within 1219.2mm, this can be cut to size directly from stock in the local market with minimal lead time.

For custom lengths (e.g., 1.5m, 1.8m, 2.1m, 2.6m, or 3m), sheets can be cut from stainless steel coils. This option is also feasible, but may require a few additional days to wait for the stainless steel sheets suppliers to cut from coils

We can accommodate any width up to 1500mm and any length as specified by the customer, ensuring flexibility for project-specific requirements.

Benefits Of Stainless Steel Perforated Sheets

► Their Resistance To Corrosion

Stainless steel is well known for the rust and oxidation it carries, which is a benefit for indoor and outdoor use. Metart Building Tech’s stainless steel perforated sheets are best used in applications where they are exposed to moisture, harsh weather, or other corrosive environments.

► Maintaining a high strength-to-weight ratio

Even with the perforation, the sheets have a significant strength, which means they can offer ample structural support without excessive weight. This makes them ideal for architectural use, where strength is required to support the building, and it is required to provide a pleasing appearance to the building.

► Their Use In Design

The design flexibility of stainless steel perforated sheets is nearly limitless, ranging from round and square holes to more intricate bespoke shapes. Metart Building Tech provides the customer's vision with unique architectural designs by offering customizable designs of perforation.

► They permit the free flow of air and light

The stainless steel perforated sheets also serve to provide light and air to the structure; thus, they are ideal for use in facades, sunscreens, and ventilation panels.

► Low Maintenance

Public stainless steel structures withstand cleaning, so they retain their polished appearance for years without effort. This is especially valuable for public restrooms, building exteriors, and other high-traffic areas.

Applications Across Industries

The many uses of stainless steel perforated sheets extend across numerous sectors, such as:

► Architecture and Construction

They are employed as decorative facades, sunscreens, stair railings, and cladding to enhance appearances and offer additional functionality.

► Industrial Screening and Filtration

Within industrial settings, these sheets are used as rugged filters for liquids, gases, or solid substances.

► Acoustic Solutions

Perforated panels are used as noise control panels in auditoriums and other offices, as well as in industrial settings.

► Safety and Security

They are perfect for protective grilles, fencing, and machine guards that require unobscured views while providing safety.

► Environmental and Ember Protection

Metart Building Tech manufactures Ember Proof Perforated Stainless Steel Sheets, which protect property in fire-prone areas by preventing ember penetration during bushfires.

Metart Building Tech: Leading the Field in Perforated Metal Products

Metart Building Tech clearly focuses on creating stainless steel perforated metal sheets with the industry’s highest quality standards to meet diverse needs. One of Metart Building Tech’s flagship products is the Ember Proof Perforated Stainless Steel Sheet, which is extremely important in protection against bushfires.

► Ember Proof Features

The ember-proof sheets are flame-resistant and specially designed to prevent the perforated stainless steel sheet from allowing embers to come in while granting ventilation essential for combustion. This is extremely important for the protection of homes and offices located in areas that face threats of wildfires.

► Custom Manufacturing

Metart Building Tech serves its clients with full customization of the stainless sheets. Clients can select the grade of stainless steel, perforation patterns, thickness, and finish, which Metart Building Tech will manufacture to meet the client’s needs.

► Architectural Expertise

The sophisticated look of the stainless steel perforated sheets adds value to contemporary architecture making them a perfect choice for modern buildings. This has made the company a partner of choice for many architects, builders, and designers, allowing them to create modern but functional solutions.

Why is Stainless Steel Preferable to Other Metal Sheets?

Though other metal sheets, such as aluminium, copper, and galvanized steel, offer perforated sheets as well, stainless steel comes with specific benefits:

Enhanced Resistance to Corrosion – Stainless steel, unlike other metals, does not need coatings to protect it from corrosion.

Hygienic – With proper care and maintenance, stainless steel does not tarnish or lose its polish, safeguarding its appearance and resilience for many years.

Environmentally Sustainable – This type of steel can be reused completely, which is good for the environment and supports upcycling projects.

Non-Combustibility – This is critical for the safety of residential and commercial buildings.

Form, Function, and Beauty

Stainless steel sheets are more than just useful — they can have outstanding aesthetic value. Used as part of stainless steel architectural projects, the perforated sheets refine the design:

Building Facades – They help enrich a building’s exterior by introducing texture and depth.

Interior Partitions – They allow for the division of offices or homes into open yet private spaces.

Ceiling Panels – They provide design and acoustical control simultaneously.

Sunshades – They inhibit direct sunlight and preserve the view outdoors.

“They offer stunning textured steel finishes such as brushed, polished, or powder-coated, which can be perfectly suited for the stainless steel architectural design,” said a designer at Metart Building Tech.

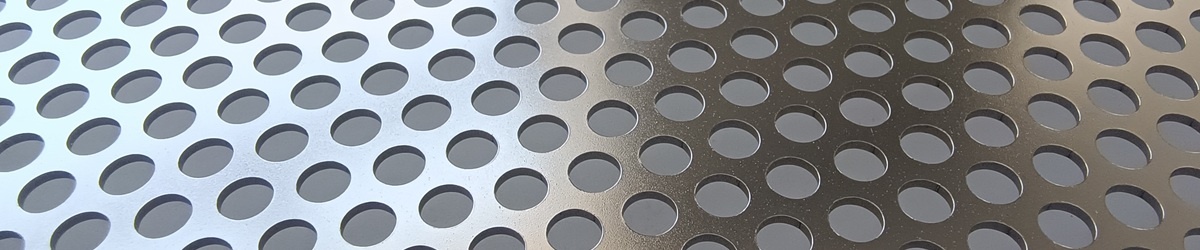

Quality Assurance and Precision Engineering

Metart Building Tech upholds meticulous standards of quality at every stage of production. Each sheet of stainless steel is sourced from premium grades, and advanced perforation techniques are employed, allowing for stringent quality checks. This guarantees repeatable function, exact tolerances, and mirror-like surfaces.

Modern manufacturing capabilities allow for tight tolerances. Thus, every perforated sheet is assayed to ensure the exact specifications of the project are met.

Stainless Steel Sheet With Holes – A Material for the Future

Stainless steel perforated sheets are the apex of strength, multifunctional capabilities, stylish appeal, safety, environmental protection, and architectural beauty. Stainless steel perforated sheets are a material that performs across industries.

Metart Building Tech is a trusted partner for architects, builders, and industries looking for premium perforated metals. The company has also furthered innovation by integrating design and safety in ember-proof bushfire stainless steel perforated sheets for regions susceptible to bushfires.

Metart Building Tech continues to provide exceeding products with modern construction and designs by combining engineering excellence with aesthetic versatility. Anyone looking for stainless steel, customizable, visually appealing, and durable products, Metart Building Tech offers stainless steel perforated sheets that serve as a beacon for reliability.

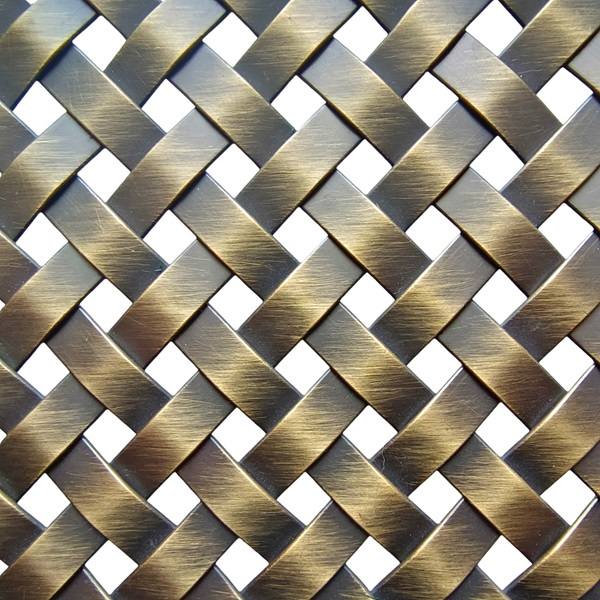

Architectural Metal Mesh made of architectural metal strips.

Architectural Wire Mesh Railing Infill Panel - Made of stainless steel decorative wires

Bushfire Grade Perforated Galvanized Sheet, Ember Protective Perf Sheet

Bushfire Ember Perforated Galvanized Sheet

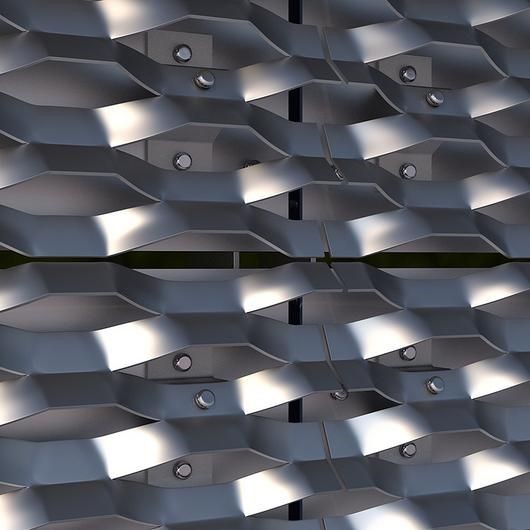

Expanded Metal Sheet is a three-dimensional sheet metal mesh that is firstly cut and then quickly stretched to form repeated diamond-shaped hole patterns.

Architectural Expanded Metal

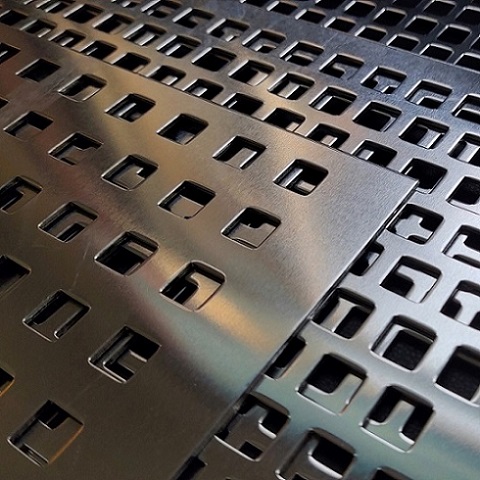

Square Hole Perforated Metal has two basic hole arrangements. One is paralleled holes pattern which is also called the straight pattern. The other one is the staggered pattern.

Square Hole Perforated Metal

Most Popular Material: AL Grade 3003, AL Grade 5052, Pre-Galvanized Steel Sheet.

Decorative Perforated Sheet

Perforated Sheets are also known as perforated metal, perforated plates, perforated mesh, punched sheets, punched metal mesh,

Standard Round Hole Perforated Sheets

©COPYRIGHT METART BUILDING TEC CO., LTD | ALL RIGHTS RESERVED | PRIVACY POLICY