What is Custom Wire Mesh Fabrication?

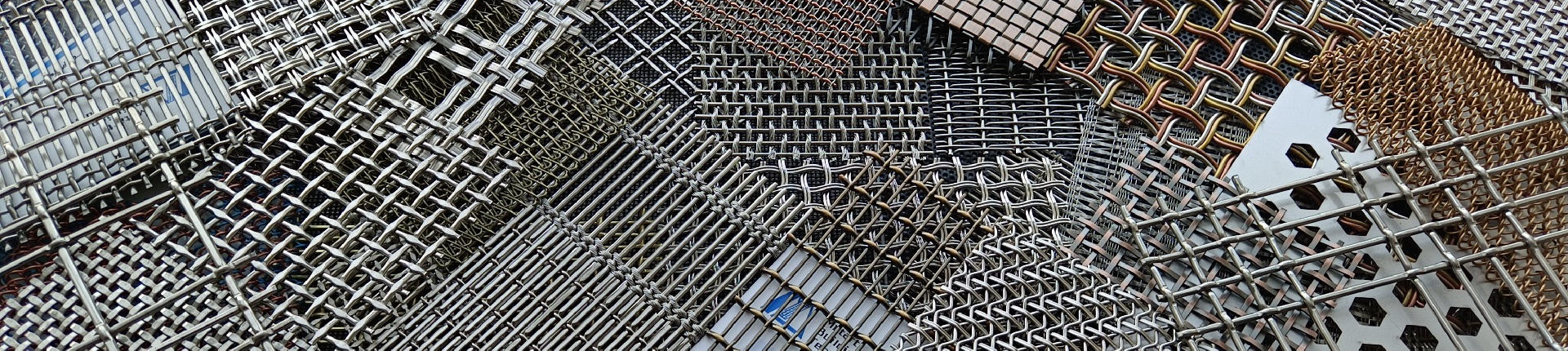

Custom wire mesh fabrication is the more specific and nuanced sphere of design and production that deals with the weaving or welding of wire mesh to custom specifications, such as custom material options, dimensions, patterns, and finishing touches. Unlike mass-produced metal mesh, custom fabrication ensures that every detail, and even wire thickness and mesh spacing, is tailored to serve a specific, design-centric purpose.

Different industries, such as architecture or designing, can now adapt precision, durability, and aesthetic perfection with the aid of the custom wire mesh fabrication, which can be used as Structure, Decoration, or Both. Custom wire mesh fabricated can be tailored to any requirement or limitless possibilities.

Why is Custom Wire Mesh Widely Sought After?

The need for the custom wire products is their perfect balance of practicality with a modern aesthetic. The custom wire mesh fabrication wire products prescribed for fulfilling the need balance in the following approaches:

• Design Indulgence – textured mesh design as well as aperture sizes can be adjusted for particular use, Wire Gauges can be tailored to meet specific requirements such as robust protection or visual appeal.

• Material Versatility – Choices such as Stainless Steel, Brass, Bronze, or Aluminum open up different options for aesthetic appearance and functionality.

• Durability and Strength – harsh environmental weather with coverage of wire mesh and maintaining its goodness is beneficial, which enhances its durability alongside its structural integrity.

Decorative wire mesh can also be used to improve interior design and in facade architecture as an aesthetic texture to the building.

Using all these specifications. Metart Building Tech can translate concepts into reality while adding beauty with functionality fulfilling bespoke needs.

Metart Building Tech: Top-Level Experts in Architectural Wire Mesh Works

Metart Building Tech has gained renown in the custom wire mesh design industry for both architectural and industrial uses. The company merges years of experience with new-age manufacturing to provide unrivaled quality to the clients.

Some of the custom fabrication offerings are:

• Tailored Mesh Patterns. Metart is capable of designing patterns that range from basic grids to advanced weaves in order to meet any design brief.

• Material Selection. Metart Building Tech provides quality metals such as stainless steel, brass, bronze, and aluminum which are important for wire mesh and architectural design for aesthetic and functional purposes.

• Precision Engineering. Every mesh panel is fabricated and engineered with exact measurements, assuring the clients the precision and perfection in fit and finish.

• Surface Finishes. Enhancing the metals with coatings, powder, and plating provides longevity and better aesthetics.

• Metart Building Tech offers beauty and functionality for partitions, decorative ceilings, safety barriers of walls, ventilation covers, and more.

Uses of Custom Wire Mesh Fabrication

The versatility of wire mesh makes it a preferred material across various industries. Metart Building Tech offers services for:

1. Architectural Facades

A building's exterior can now be equipped with wire mesh fabrications, which can perform various functions of shading and ventilation while serving as a distinctive design feature. Custom mesh panels offer visual depth and texture thanks to a building's energy efficiency and aesthetics.

2. Interior Design Features

From grand hotel entrances to contemporary offices, bespoke wire mesh interiors can be used in partitions, balustrades, ceilings, and wall claddings which resulting in and striking interiors which feature a mixture of transparency and structure.

3. Safety and Security-Based functions

For protective enclosures, fencing, and security barriers, high-strength wire mesh made of high-tensile stainless steel wires with a tensile strength range up to 1100MPa serves as an ideal protective enclosure offering optimum durability and visibility.

4. Industrial Grade Filtration and Screening

In wire mesh industrial settings, the wire mesh products serve as filtration, separation, and reinforcement components that are tailored to operational requirements.

5. Artistic Installations that are Bespoke

Due to the wire mesh's texture, light interaction, and structural design potential, it is increasingly popular with artists and designers for bespoke sculptures, installations, and public art.

The Metart Building Tech Advantage

With Metart Building Tech, your custom wire mesh fabrication comes with:

• Customization that is unmatched - Each of our mesh products is bespoke designed to meet your exact specifications.

• Comprehensive Project Overview - Metart has provided solutions to projects across the globe, showcasing the capability to address various cultural and environmental considerations.

• Commitment to Quality - Long-lasting performance is guaranteed through the use of premium raw materials and strict quality assurance processes.

• Collaborative Approach - Every project is attended to with great detail as Metart’s personnel work shoulder to shoulder with architects, designers, and contractors, ensuring smooth project adaptation.

Metart Building Tech has become a trusted partner for multifaceted and visionary projects by integrating aesthetics with enduring strength and engineering precision.

Sustainability in Custom Wire Mesh Fabrication

Sustainability is at the heart of custom wire mesh fabrication. With a goal of fostering environmentally considerate practices, Metart Building Tech uses recyclable materials such as stainless steel and aluminum, greatly reducing the ecological footprint while enhancing stainless steel’s mesh longevity. Their precise fabrication methods not only minimize waste, but many designs are aimed at promoting energy efficiency in structures.

This makes custom wire mesh a stylish choice as well as a sustainable, environmentally-friendly design solution.

From Concept to Creation: The Fabrication Process

Metart Building Tech gives careful attention to detail to ensure every mesh product manufactured is precise:

• Consultation & Design - Forming the client’s insight, functional requirements, and environmental factors for the design.

• Material Selection - The chosen metal and its finish need to address performance and visual elements.

• Precision Weaving or Welding – Implementation of advanced machinery to inscribe the exact design and spacing.

• Finishing & Treatment – Protective coatings or polishes to improve the appearance and prolong the lifespan.

• Quality Assurance – Examination of each panel to ensure compliance with rigorous international standards.

Every custom wire mesh project is flawlessly executed with this start-to-finish approach.

Why Architects and Designers Choose Metart Building Tech?

Realizing design visions is made possible with Metart’s custom wire mesh fabrication. Our delivery of unique patterns and perfect finishes, as well as sturdy sound solutions, earns their favor with leading Metart wire mesh designers and architects.

The company caters to custom requests from sleek minimalism to bold statement facades.

Conclusion

Custom wire mesh fabrication is a statement of innovation and elegance in the modern built environment. It transcends as a background element to a defining feature of architecture and design wire mesh blends. It is the built environment’s need with contemporary design alongside functionality.

Metart Building Tech is one of the factories leading this evolution with unmatched customization, craftsmanship, and bespoke woven wire mesh architectural details. Transferring concepts to building and industrial component reels is done with style and precision, whether it is augmenting the structure’s exterior skin, making an artistic centrepiece, or adding industrial component reels.

Metart Building Tech's custom wire mesh fabrication gives the best results of art and engineered design for these demands of outstanding craftsmanship and individualistic design.

+86 158 0318 7372 / +61 435 598 786

+86 158 0318 7372 / +61 435 598 786

+86 158 0318 7372 / +61 435 598 786

+86 158 0318 7372 / +61 435 598 786