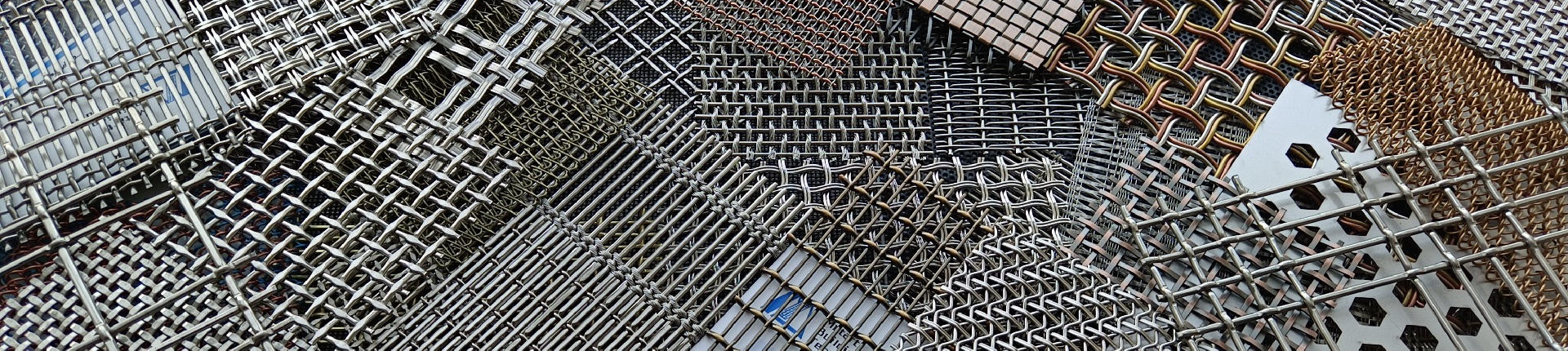

Round Perforated Metal Sheets: Their Simple Yet Elegant Features

To manufacture round hole perforated metal sheets, circular holes are punched into sheets of metals like aluminium, stainless steel, galvanized steel, and mild steel. These sheet metals can also withstand different climates, ensuring their longevity and strength, and reducing the cost of maintaining them in the long run.

The round hole pattern remains the most popular perforation style because it offers:

• An ideal strength-to-weight ratio

• Ventilation and drainage efficiency

• A sleek, modern aesthetic

• Ease of customization for finish, size, and pattern

• Metart Building Tech – Crafting Excellence in Every Sheet

As a supplier and manufacturer, Metart Building Tech specializes in the production of round hole perforated sheets, ensuring we meet the required international standards. With years of industry experience, we leverage modern CNC punching equipment and rigorous quality standards to produce sheets that provide consistent functionality and flawless aesthetics.

Their product range includes:

Stainless Steel Round Hole Sheets – corrosion-resistant and safe for hygienic applications, especially in architectural and food-grade industries.

Aluminium Perforated Sheets – Excellent for cladding and for acoustic and ventilation systems, these sheets are lightweight and durable.

Galvanized Steel Perforated Sheets – These perforated meshes are ideal for outdoor installations, being cost-efficient and resistant to weather conditions.

Mild Steel Sheets – These are strong, being easy to fabricate, and are ideal for heavy industrial applications.

What Sets Metart’s Round Hole Perforated Metal Sheets Apart

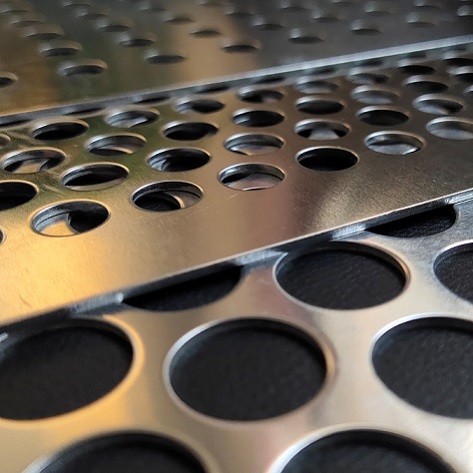

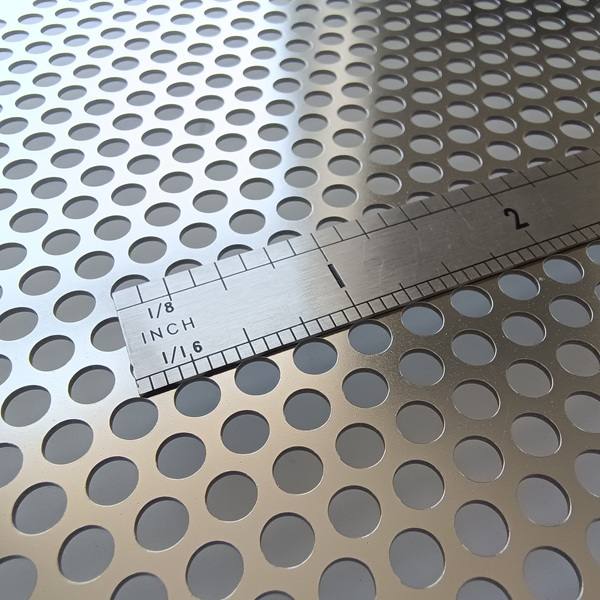

1. Superior Precision

TThrough Metart’s industry-leading technology and processes, which ensure hole-to-part accuracy, consistent hole diameter, and smooth edges free from safety and aesthetic-compromising burrs.

2. Versatile Customization

TProject-specific requirements such as hole diameters, open area percentage, and sheet thickness, as well as their corresponding patterns, are fully customizable.

3. Options for Materials and Finishes

TAside from natural metal mill finishes, customers may choose from powder coating, PVDF painting, or polishing for functional and aesthetic protection.

4. Flexible Shaping

TMetart’s perforated sheets are suited for heavy-duty environments as they maintain impressive load-bearing capacity even with high levels of perforation.

5. Corrosion and Weather Resistance

These sheets retain their integrity, withstanding harsh climates and corrosive conditions from marine environments to industrial plants.

Applications across Industries

Countless purposes exist for Metart Building Tech’s round hole perforated metal sheets across multiple sectors.

• Architectural & Design Applications

• Striking building facades

• Balcony panels and railings

• Sunshades and louver systems

• Interior partitions and ceiling panels

• Industrial & Mechanical Uses

• Filtration screens for liquids and gases

• Ventilation systems and HVAC registers

• Noise management control panels for acoustics

• Agricultural & Environmental

• Grain drying screens

• Equipment for sorting seeds

• Protective covers for crops and food products

• Security & Safety

• Machine guards

• Anti-vandal panels

• Protective enclosures for sensitive equipment

Why Industry Professionals Choose Metart Building Tech?

Choosing Metart Building Tech has become the preferred partner for architects, engineers, and project managers due to:

Decades of expertise in precision perforation manufacturing

Global supply capability ensuring timely delivery worldwide

Technical support from concept to installation.

Sustainable manufacturing practices that reduce waste and optimize energy use

A proven track record in delivering on complex, large-scale projects

The Metart Manufacturing Process – Where Precision Meets Innovation

The intricate round hole patterns on sheets are produced at high speeds and with absolute accuracy at Metart’s production facility using their cutting-edge CNC punching machines. Stringent quality checks are performed on each sheet, including:

• Dimensional accuracy

• Uniformity of perforations

• Surface smoothness

• Strength testing

Such meticulous attention to detail ensures functionality and beauty for all products, enabling effortless integration into installations designed for beauty, functionality, or both.

Custom Perforated Mesh Solutions for Unique Projects

Unlike other manufacturers, Metart Building Tech goes beyond creating standard sheets and works directly with clients to develop customized perforated metal products. Be it a non-standard sheet dimension, a specific detailing for custom branding, or a perforation pattern added to it, the engineering team collaborates to realize the design into an exact piece.

Customizations include but are not limited to:

• Decorative gradients with variable hole diameters on a single sheet

• Architectural curved or shaped accent panels

• Custom alloys for corrosive or high-heat environments

• Sustainability and Eco-Friendly Manufacturing

Metart works to lower the impact through:

• Recycling materials

• Using energy-efficient machinery

• Improving processes to reduce waste

With a focus on sustainable practices, the company not only supports eco-friendly projects but also allows clients to achieve green building certifications with the products supplied.

Conclusion

More than simply sheets of metal, round hole perforated metal sheets serve as structural solutions, as well as design and function elements. If manufactured well, these sheets of metal could enhance the aesthetic value of a building, its mechanical efficiency, and ensure reliable performance over time.

Metart Building Tech has mastered this craft. They have unparalleled precision in manufacturing, a wide selection of materials, and a commitment to customer satisfaction, which makes them the preferred supplier to architects, engineers, industrial planners, and designers.

Metart can provide sleek aluminium architectural façade panels, stainless steel screens for hygienic settings, and rugged outdoor galvanized steel sheets. They have the technology and expertise to exceed expectations.

Investing in a building tech solution prepared by Metart means choosing innovation and quality. It means investing in a building tech solution that has been relied on for decades of reliable performance.

+86 158 0318 7372 / +61 435 598 786

+86 158 0318 7372 / +61 435 598 786

+86 158 0318 7372 / +61 435 598 786

+86 158 0318 7372 / +61 435 598 786